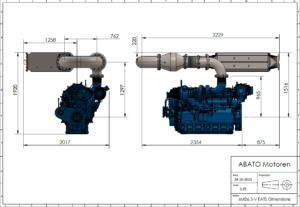

Stage-V Baudouin marine engines

The M26.3 family is finished Stage-V certified by Motors Baudouin.

Why a Baudouin Stage-V engine?

These engines are designed from the drawing board for maritime purposes. As a result, the engine has inspection covers, loose liners and a number of features such as readable thermometers. The engine also has water-cooled manifolds and turbos, which means that the heat emission in the engine room remains limited. The design ensures, for example, that maintenance can be easily carried out on board and that the engine can be overhauled on board if necessary.

The overall performance of the engine is without a doubt solid. The documentation of the engine has also been expanded and options such as a PTO are possible.

These are the capabilities:

| engine type | rating | kW | pk | / Min |

|---|---|---|---|---|

| 6M26.3 S5 IWP | Continuous Duty (P1) | 441 | 600 | 1800 |

Heavy Duty (P2) | 485 | 660 | 1800 | |

Heavy Duty (P2) | 551 | 750 | 2100 | |

Intermittent Duty (P3) | 599 | 815 | 2100 | |

| 6M26.3 S5 IWA | Continuous Duty (P1) | 490 | 666 | 1500 |

Continuous Duty (P1) | 441 | 600 | 1800 | |

| 12M26.3 S5 IWP | Continuous Duty (P1) | 883 | 1200 | 1800 |

Heavy Duty (P2) | 970 | 1320 | 1800 | |

Heavy Duty (P2) | 1030 | 1400 | 2100 | |

Heavy Duty (P2) | 1104 | 1500 | 2200 | |

Intermittent Duty (P3) | 1214 | 1650 | 2300 |

| Power class | Description |

|---|---|

| Continuous duty | Continuous use with little or no variation in speed/load. Average engine load: 100%. Annual useful life: unlimited. Usage under full load: 100% |

| Heavy Duty | Continuous operation with frequent variations in speed and load. Average engine load: 80%. Annual service life: < 5.000 hours. Use under full load: 8 hours per 12 hour period (67%). |

| intermittent duty | Varied use with a lot of variation in speed and load. Average engine load: 60%. Annual service life: < 3.000 hours. Use under full load: 2 hours per 12 hours (17%). |

Both Baudouin Stage-V engines are supplied including:

Cooling system

- Dual high and low temperature cooling circuits

- Ready for hopper cooling

- Fresh water pump motor driven for the HT system

- Self-priming water pump driven by the engine for the LT system

- Flexible rubber bellows on engine water circuits

- Thermostatic valve low water temperature circuit (supplied separately).

Lubricating oil circuit

- Lubricating oil cooler mounted on the engine

- Removable lubricating oil filters

- Manual drain and pre-lubrication pump motor

- Engine-driven lubricating oil pump

Start-Stop-Cruise control systems

- 24V DC electric ignition

- Common rail electronic injection

- Engine mounted ECU (standard: Bosch)

Fuel circuit

- Electronic injection with common rail system

- High Pressure Fuel Pump

- Double-walled high-pressure pipes

- Duplex screw-on fuel filters

- Fuel leakage container

- Water separator with built-in 24 VDC suction pump

- Connection for flexible hoses

Intake and exhaust gas circuits

- Heat-insulated turbochargers

- Low temperature charge air coolers

- Dry air filters with crankcase ventilation via recycler

- Intake air preheater

- Freshwater cooled exhaust manifolds

- Exhaust gas expansion bellows after the engine with counter flanges

The IWP certificate applies for diesel-electric propulsion.

The IWA certificate is applicable for auxiliary generator sets and pumps with constant speed.

The certificate numbers are:

6M26.3-V IWP: e6*2016/1628*2016/1628PV4/D*0003*00

6M26.3-V IWA: e6*2016/1628*2016/1628AC4/D*0001*00

12M26.3-V IWP: e6*2016/1628*2016/1628PV4/D*0004*00

Common rail technology, what is the advantage of this?

The Baudouin engines are equipped with a common-rail injection system with piezo injectors. Common rail technology has been used in the automotive world since the arrival of EURO III. That brought a big improvement in fuel consumption and engine torque.

A common rail engine has several injection moments per cycle. In addition, different amounts can be injected at a time. This is recorded in the so-called 'engine mapping'. Due to the higher pressures, the fuel is finer and better distributed. This creates a more efficient combustion with less formation of NOx and soot particles.

Also, due to the use of common-rail technology, the permitted back pressure after the turbo is many times higher. This allows a compact post-gas treatment package to work. This saves considerable installation space and costs.

The dimensions of the DOC-DPF-SCR combi for the large V12 engine of 1650 hp are very compact. The orientation of the package is flexible, so it can be positioned in a way that it should fit into most engine rooms.

Finally, the Stage-V waste gas treatment package is also easy to maintain, because it can be unscrewed and the elements can then be easily inspected and replaced. So a really good solution for the maritime world!

The 6M26.3 engine is a 6-inline engine and has a displacement of 16 liters. The larger 12M26.3 is a 32 liter V12. The models are completely improved versions of the proven and well-known M26.2 predecessor.

Operating system

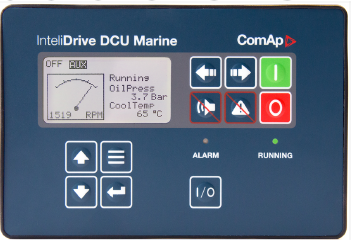

The engine is equipped with an ECU from Bosch. This ECU communicates with a Comap ID DCU. The Comap ID DCU is again coupled to the bridge panel and simultaneously to the control of the after-treatment system.

The after-treatment system is linked to the optional industrial PC that connects to the internet via a GSM modem.

Bridge panel 5,7”

A 5,7 inch color screen. TFT display with a resolution of 320 x 240 pixels. Graphical interface partially customizable via programmable active buttons. Communication via CAN. Automatic brightness control. Temperature from -20 to +70 degrees Celsius. The front is waterproof (IP65). Cutout 175-115mm.

Bridge panel 12”

A 12,1 inch color multi-touch screen. TFT display with a resolution of 1280 x 800 pixels. Graphical interface that is customizable. Communication via CAN or Ethernet. Sunlight-readable screen with a light intensity of 1000 cd/m2. Automatic brightness control. Temperature from -30 to +70 degrees Celsius. The front is waterproof (IP65). Cutout 311 – 206mm.

Monitoring

- Service meter

- Hour meter

- Alternator malfunction

- Engine oil temperature indication

- Engine lubricating oil temperature high (alarm)

- Engine oil pressure indication

- Engine oil pressure low (alarm)

- Engine oil pressure very low (alarm)

- Indication of the temperature (coolant)

- Temperature high (alarm)

- Fuel leakage injection lines (alarm)

- Overspeed (alarm)

Remote monitoring

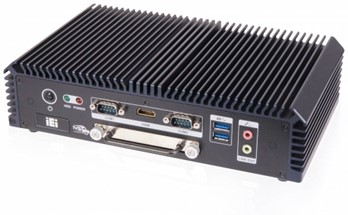

It is possible to monitor the condition of the engine remotely, i.e. outside the ship, and to receive any signals.

This makes it easy to assist remotely in the event of malfunctions. Notifications can also be passed on in advance.

Features:

Industrial fanless mini pc. Aluminum housing. Dust and shock resistant. Suitable for 'harsh environments'.

Connects to the outside world via the GSM network with supplied modem. This allows you to log in to the system.

Ambient temperature | 20 oC to 65oC |

Humidity | 10% to 95% at 40oC non-condensing |

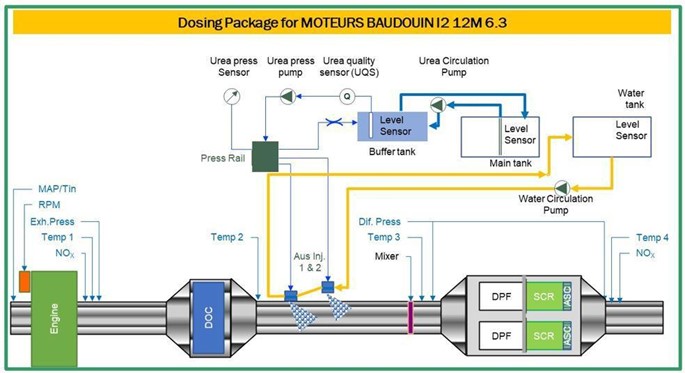

After-treatment system Stage V: build-up

The complete after-treatment system, shown in the adjacent figure, consists of:

- The DOC with inlet and outlet cone

- The modular emission aftertreatment system

- The urea mixer mixing pipe

- The urea dosing package

- The main tank pack

- The wire harness

- The hydraulic package

- The control box

The system concept will be attached to the turbo outlets, each turbo outlet will have its own DOC and mixer. The package contains 10 elements; (2 rows of 5). The Modular Emissions Aftertreatment System is a standardized modular emissions package developed for marine, generator sets and other large industrial applications.

Different emission technologies can be fitted within the same design, SCR (SCR only for Marine IMO TIER III), SCR+ (with DOC and ASC for TIER 4 F and EU Stage IV), a stage V package (with DOC, DPF, SCR, ASC) and SCR + ASC + OC for gas engines and greenhouses.

The temperature sensors, NOx and oxygen sensor, the pressure drop across are an integral part of the package. System components are selected to maintain emissions in line with requirements, taking into account typical lifecycle expectations for marine and CHP applications

The service intervals can be synchronized with the engine maintenance and overhaul intervals (provided the correct fuel and lubricating oil is used).

The catalytic converter service is clearly structured. The system is designed to last. All elements can be easily removed by hand and no special tools are required. The weight of an individual catalytic converter element is less than 20 kg. The fasteners are made of stainless steel, but even after many heating and cooling cycles, they can be easily removed and replaced with new bolts if damaged or overloaded.

The complete exhaust package is made of premium stainless steel quality: 316 (L).

It is corrosion resistant both inside and out and resistant to urea, ammonia, sea water and many other unknown chemical components that may be present in exhaust gases.

The assembly is supplied with a DN PN6 flange set of the selected pipe diameter. The flanges are not welded to the pipes, which allows installation according to the customer's wishes. ABATO is happy to make a specific design of the inlet/outlet of the DOC - mixing pipe - SCR for each project in conjunction with the customer's needs. This way we can design the system in the engine room. All our major components come with a 20 year spare parts availability guarantee. The figure below shows the 12M26.3 with the compact integrated after-treatment system

The DOC with inlet and outlet cone

The DOC substrate (diesel oxidation catalyst) is made of metal Fecraloy® and coated with a powerful and stable oxidation coating. The coating enables and promotes passive regeneration of the DPF (diesel particle filter) and, if necessary for emergencies, also active regeneration through Diesel HC (hydrocarbon) dosing.

The DOC catalytic converter comes with an inlet and outlet cone that tapers the DOC to the diameter of the exhaust bend and compensator after the turbo.

At the inlet of the DOC is a 1 meter stainless steel straight tube with the connection ports for the sensors and actuators listed below:

- Temp 1 sensor

- Back pressure sensor exhaust system

- DO NOTx 1 sensor

- Diesel dosing unit

The assembly is supplied with a DN PN6 flange set, which is correlated with the pipe diameter. The flanges are not welded to the pipes, which allows installation according to the customer's wishes.

The urea mixer or mixing pipe

The system is always supplied with a 2-stage low pressure drop mixer. This technology enables airless urea dosing. This method is cost effective as a compressor is not required. Because no compressed air is required, the energy required to operate the system and thus the CO2footprint of the system is virtually zero.

- There is no overdose of urea

- There is no need for an oversized catalyst pack because we can use the total surface area of the catalyst;

- System diagnostics improve thanks to homogeneous reading of exhaust emissions

The urea dosing package

Electronic control unit

The dosing system uses an ECU as the center of the system. This Electronic Control Unit (ECU) has been developed as a link between the engine and the emission aftertreatment system. The ECU controls the AUS (Urea/AdBlue) dosing, tanks and pumps while constantly monitoring performance, engine operating conditions and pressure drop across the exhaust. A number of parameters are stored in the ECU, according to the Stage-V regulation. Each engine has its own individual controls.

Most important features

- OEM specifications

- Robust construction

- User-friendly Windows interface

- Suitable for all engines and exhaust systems

- Suitable for all on-road / off-road and marine applications

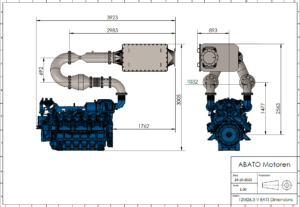

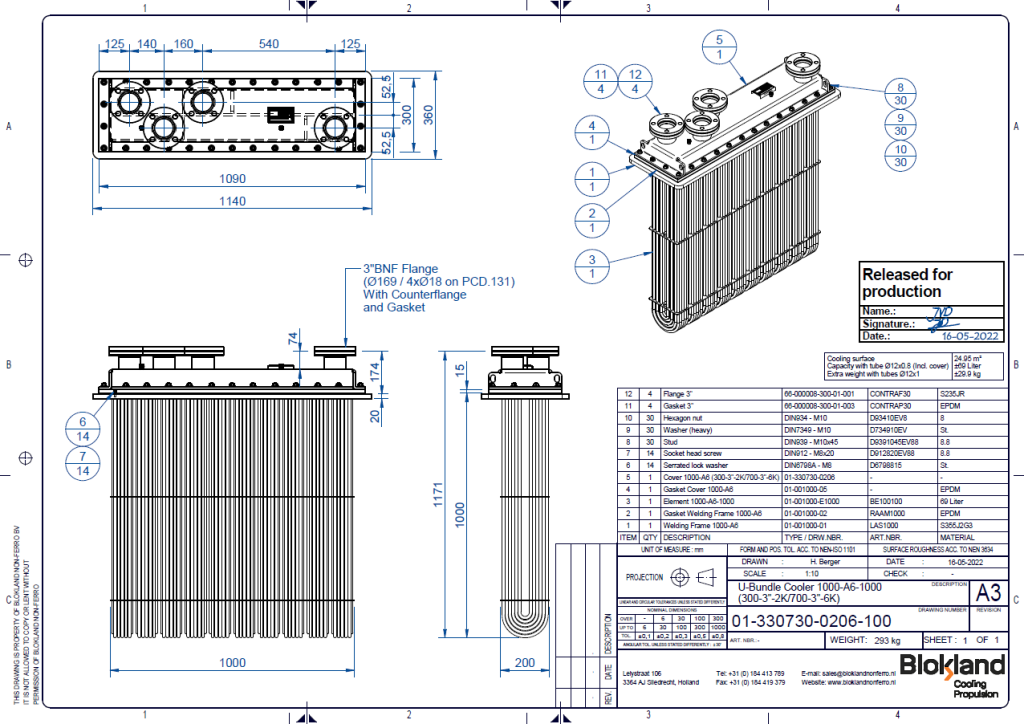

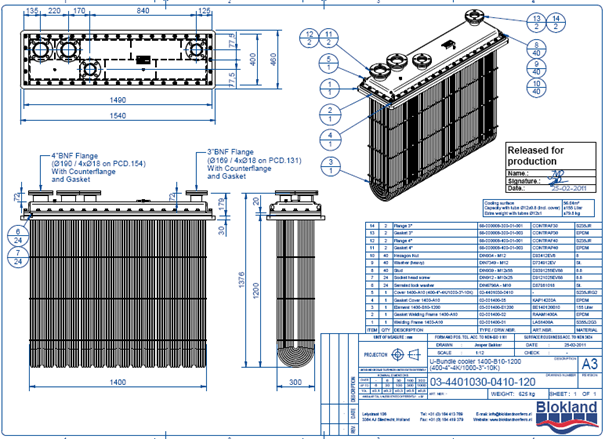

Hopper cooler

There is also the option to add a Blokland box cooler. These are shown below.

gearboxes

You have also come to the right place at ABATO Motoren for a suitable gearbox. Baudouin produces gearboxes for its marine engines. You can order these through us as a certified Baudouin dealer. For more information about the different gearboxes, please view our gearboxes page.

Drawings EATS

![]() ABATO – 12M26.3-V_EATS_Inlet_assembly

ABATO – 12M26.3-V_EATS_Inlet_assembly

![]() ABATO – DOC_Assembly_Ø 440×130 mm_IN8inch_OUT10inch

ABATO – DOC_Assembly_Ø 440×130 mm_IN8inch_OUT10inch

![]() ABATO – ETA BOX 12”- 2×3 – IN 2xDN250 – OUT 1xDN350

ABATO – ETA BOX 12”- 2×3 – IN 2xDN250 – OUT 1xDN350

![]() ABATO – ETA BOX 12”- 2×3 – IN 2xDN250 ROT 90° – OUT 1xDN350

ABATO – ETA BOX 12”- 2×3 – IN 2xDN250 ROT 90° – OUT 1xDN350

![]() ABATO – MIX PIPE DN250 2(BL)WC L 1,13m – BREAK UP 25° – PN6

ABATO – MIX PIPE DN250 2(BL)WC L 1,13m – BREAK UP 25° – PN6

![]() ABATO – TANK UB V6 ASSY 7L SS QS 1MP 24V R0.6 7.89 PR1F RR1x7.89

ABATO – TANK UB V6 ASSY 7L SS QS 1MP 24V R0.6 7.89 PR1F RR1x7.89

Request a quote

Are you interested in one of the above models?

Let us know which model you are interested in and we will send you a quote as soon as possible!

Contact details

- Platinum avenue 10

5234 GH, 's-Hertogenbosch

The Netherlands - info@abato.nl

- Phone: +31 (0)88 2228600

- KvK 54206839

- VAT NL851215099B01