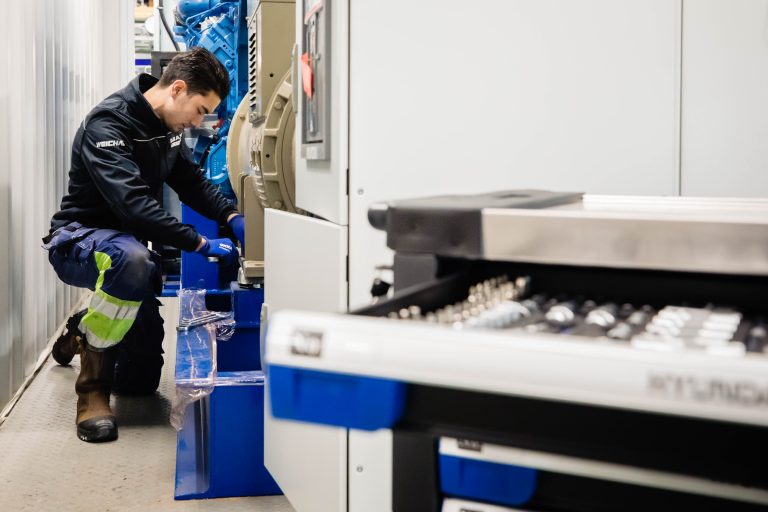

Emergency power generator maintenance: Why is it important?

The purpose of an emergency power generator (NSA) is to always be able to take over the regular power supply. To ensure that this is possible, you must maintain the emergency power generator. In addition to the annual maintenance, part of this maintenance can also be done by yourself. In this way, many problems can be identified and prevented early. In this article we explain the different elements of proper maintenance of an NSA and what you can do yourself.

Monthly Inspection

To identify problems early, it is important that you perform a visual inspection on a regular basis. You can carry out this inspection yourself. You look at whether the generator starts quickly, there are no leaks or strange noises, whether the correct voltage and frequency are being achieved and whether the liquid levels are correct. In this way you prevent that the generator is not found to be in order until the annual maintenance.

If there is no one with the right expertise or enough time for the inspection, ABATO Motoren can do this for you. This inspection can also be done together with an internal employee. In this way, the internal employee can learn to eventually do this inspection himself.

Annual inspection and mandatory inspections

In the Netherlands, an emergency power generator must comply with the NEN 3140 standard. This standard requires an annual inspection, a safety inspection, visual inspections and record keeping. ABATO Motoren is certified to perform this inspection according to the NEN 3140 standard. Since 2016, the SCIOS inspection has to be done. The SCIOS inspection concerns a inspection for combustion plants, to check whether they meet the environmental and safety requirements. ABATO motors is certified to also perform these inspections and can maintain your emergency power generator. The SCIOS inspection can be combined with the annual maintenance. How often the various inspections have to take place depends on the power of the generator.

test run

Test run is an important part of your NSA's inspection. This can be taxed or unloaded. During an unloaded test run, it is checked whether the generator starts, whether the correct voltage and frequency are reached and whether the motor of the NSA is running stably. We recommend that you run a no-load test for a maximum of five minutes. This is because an unloaded test run for too long is bad for the engine.

During a loaded test run, it is checked whether the generator can deliver the desired power continuously and stably. This is recommended at least once a year. This can be done by testing the NSA with the network or with an external resistor. We advise you to have the NSA taxed test run once a year. However, if no-load test is performed more often, it is wise to also test run under load.

Do you have questions about maintenance? We are happy to help you!

If you have any questions about maintenance, you can always contact us. Please contact us via our contact page, call +31 (0)88 2228600 or mail to info@abato.nl. In addition, you can also calculate your maintenance yourself if you already have a generator. This can be done by using our maintenance calculator.

Contact details

- Platinum avenue 10

5234 GH, 's-Hertogenbosch

The Netherlands - info@abato.nl

- Phone: +31 (0)88 2228600

- KvK 54206839

- VAT NL851215099B01